02.04.2020/Posted by:istadmin

ISTA-4 – SOLVING A GREAT PROBLEMS ON THE LARGE FACILITIES

Until recently, there was no solution of the problems of bulk material hanging at the extra large facilities.

In the case of huge bunkers (up to 60,000 tons), it is efficient to use the magnetic and impulse units, industrial vibrators or even sledgehammers is not possible. For such facilities (over 1000 tons), a unique system of air impulse cleaning based on the ISTA-4 tm air cannons was developed.

WHAT IS THE DIFFERENCE?

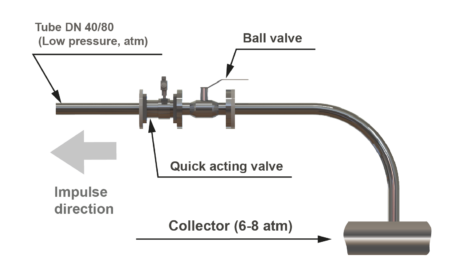

Instead of an individual receiver for each aircannon (as in the ISTA-3 tm), the system based on a number of the ISTA-4 tm air cannons is powered by compressed gas from one common receiver (collector).

Due to the speedwork of the valves, made by the SVT tm echnology, optimum number of air cannons, connected by a common collector, can effectively operate simultaneously, destroying the hanging and minimizing the irreducible (maybe “died”) residue of material in the bunker.

UNDAMENTAL CHARACTERISTICS OF ISTA-4-40

| Working gas pressure, MPa | 0.6 – 1.0 |

| Diameter of cross section, m | 0.040 |

| Volume of reservoir (collector), m3 | is not limited |

| Time of valve opening/closing, ms | 0.001 |

| Length of pipe (not included), m | 1.5 – 4.0 |

| Mass, kg | 15.5 |

FUNDAMENTAL CHARACTERISTICS OF ISTA-4-80

| Working gas pressure, MPa | 0.6 – 1.0 |

| Diameter of cross section, m | 0.080 |

| Volume of reservoir (collector), m3 | is not limited |

| Time of valve opening/closing, ms | 0.001 |

| Length of pipe (not included), m | 1.5 – 4.0 |

| Mass, kg | 32.5 |

INDIVIDUAL DESIGN

The individual design is reduced to calculation and design of the collector, as well as the number and mutual arrangement of air cannons for each facility.

The collector is usually made of hermetically connected pipe segments, which will cover all problem areas in terms of hanging outside the bunker. The collector, assembled from the pipe sections, combines low cost and high safety.

DESIGNS EXAMPLES

The pneumatic collapse system with a ring pipe collector with internal diameter of 300mm, to which 24 air cannons of the ISTA-4 tm are connected, was first installed in 2004 on a standard concrete silo with a capacity of 6000 tons of bulk material and allowed to solve the problem of hanging in an automated fashion. Unsorted residues before the adoption of the system were 1500 tons, now do not exceed 300 tons. After the introduction of the system, there was no need for manual silo cleaning. Now the system on four silos is in industrial operation during thirteen years.

The ISTA-4 tm air cannons have two sizes ISTA-4-40 tm / ISTA-4-80 tm – the difference in the cross-section diameters (40mm and 80mm). The delivery includes all necessary documents and certificates for legal operation in any production.

TYPES OF FACILITIES, EQUIPPED WITH THE ISTA-3 TM AND ISTA-4 TM SYSTEMS

Bunkers and silos

Often during transportation and storage of various bulk materials in the bunkers (silos), it occurs the hanging of the material.

Bulk material hanging in bunkers makes it difficult to unload, may cause a decrease of productivity of the whole line (or even its stopping), product degeneration, which causes serious material consequences.

Heat exchange surfaces of boiler units

During the combusting the various types of fuel in boilers, combustion products contain ash small parts, which settle down on the radiation and convective surfaces of the boiler units heating and heat exchangers. These deposits significantly reduce the heat transfer, and accordingly the efficiency of the installation.

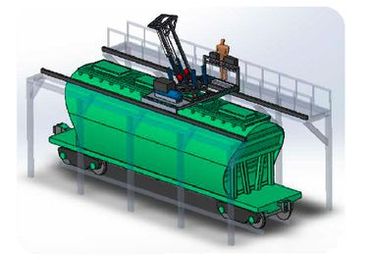

Wagons cleaning

In the summer period, the unloading the bulk material from wagons is often not a problem, however, in the winter period, the materials are frozen. During the unloading by means of rotary wagon dumper, some of the frozen material remains. For the final cleaning of wagons the manual labor is used, which essentially slows down the process (from several minutes to several hours).

Combining the system

If at the facility, equipped with an industrial vibrator, vibrating bottom or polymer spraying, the problem of bulk material hanging is not solved completely, we recommend to do without its dismantling, and to supplement the existing system with the ISTA-3 tm air guns. Such a combined systems produced good results on a number of facilities.

Cyclones, flues, bag filters

The exhaust gas, contained various small particles, passes through the mechanical cleaning stages, for example in the units such as cyclones. Gas passes through the cyclone, with deposits accumulating in the various internal parts of the housing (in the recirculation zones), which subsequently reduce the speed of the gas flow and, consequently, the cleaning.

- All

- Chemical industry

- Construction industry

- Metallurgy industry

- Power industry

- Food industry

- Pulp & Paper industry

- Mining industry