02.04.2020/Posted by:istadmin

ISTA-3TM AIRCANNON IS A SAFE AND EFFECTIVE METHOD OF FLUIDIZATION OF LOOSE MATERIALS IN INDUSTRIAL BUNKERS.

PROBLEM

Tens of thousands of industrial enterprises need to transport and store the bulk materials. Impossibility of stable, automated unloading of material from bunkers, silos, transport systems, leads to a loss of time and money. A similar problem is to reduce the efficiency of heat exchangers, filters, cyclones due to the adherence of material to the working surfaces. In this case, the losses are even more expressed.

POPULAR DECISIONS

Sledgehammer strikes, industrial vibrators, magnetic and impulse units have a general lack – the impulse is attached to the outer walls of industrial bunkers. The harder the wall, the smaller the proportion of the impulse reaches the material inside the object.

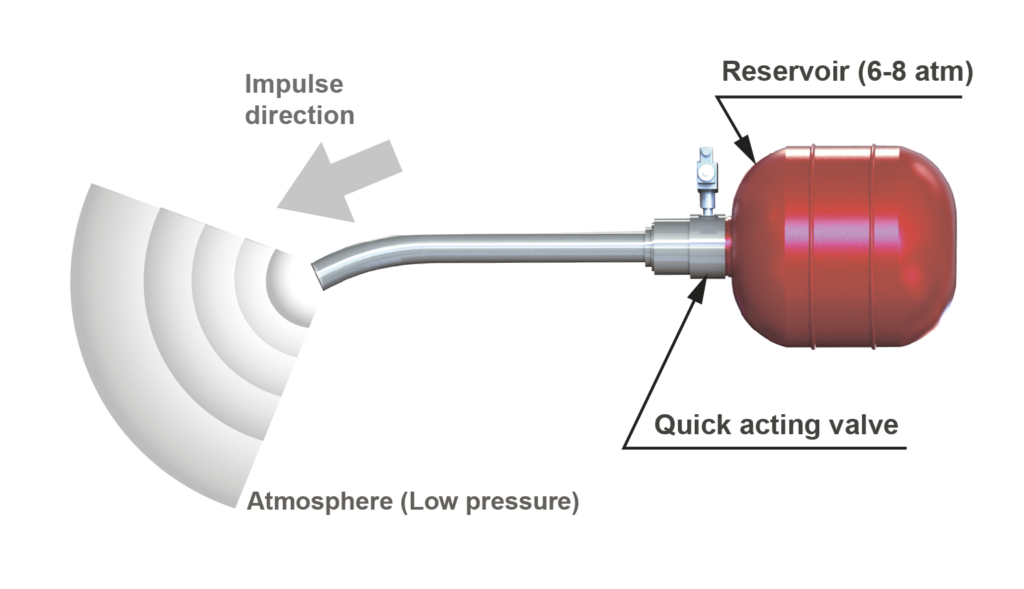

Aspiration has direct effect on the bulk material, but does not create an impulse. Air cannons – make an impulse directly to the material, so its have spread in the world, since the 60’s. Until recently, its distribution was limited to drive quality problem – compressed air. Now for most plants – this is not a problem.

OUR DECISION

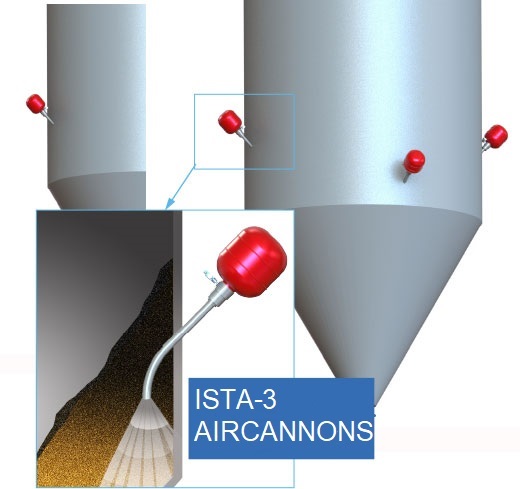

Based on the modern knowledge of the behavior of bulk materials and our experience, we offer the effective individual solution for each facility. Each solution is based on the location at the facility of the required number of air cannons, acting on the material in “critical” locations so that a minimum impulse can provide the descent of large material masses.

UNIQUENESS OF THE ISTA AIR CANNONS

Efficiency is achieved due to the fact that the ISTA-3tm air cannons are used, protected by patents of Russian Federation, the USA and Germany, an unique pneumatic valve of the KBtm series based on the SVT®echnology. Ultra-fast opening of the valve of the KBtm series for 1 ms allows to convert the energy compressed air in the receiver into the impulse with an unusually high efficiency.

LINE OF STANDARD SIZES

25 years of experience in equipping the enterprises with air cannon systems led to the development of the ISTA-3 tm standard sizes line of air cannons of different capacities. It allows to implement optimal designs in the “price-quality” scale for each industrial facility. If the bunker is very large (for example, with a capacity of more than 1000 tons of bulk material), it is proved that the solution is better to build on the basis of the ISTA-4 tm cannons.

| Parametrs | 0,5l | 1l | 2l | 5l | 10l | 25l |

|---|---|---|---|---|---|---|

| Н, mm | 230 | 170 | 210 | 280 | 360 | 760 |

| D, mm | 90 | 180 | 180 | 250 | 250 | 250 |

| Weight, kg | 3 | 1,5 | 3,2 | 4,6 | 6,2 | 21,0 |

| DN, mm | 40 | 28 | 40 | 40 | 40 | 40 |

| View |  |  |  |  |  | |

| Article | I3-005-40-R-SB | I3-01-28-R-SB | I3-02-40-R-SB | I3-05-40-R-SB | I3-10-40-R-SB | I3-25-40-F-SB |

| Parametrs | 50l | 50l | 50l | 100l | 100l | 150l |

|---|---|---|---|---|---|---|

| Н, mm | 500 | 580 | 580 | 680 | 680 | 1700 |

| L, mm | 760 | 760 | 760 | 1040 | 1040 | 550 |

| Weight, kg | 21,0 | 38,0 | 38,2 | 61,0 | 61,0 | 75,0 |

| DU, mm | 40 | 80 | 80 | 80 | 80 | 100 |

| View |  |  |  |  |  |  |

| Article | I3-50-40-F-SB | I3-50-80-F-SB | I3-50-80-G-F-SB | I3-100-80-F-SB | I3-100-80-G-F-SB | I3-150-100-F-SB |

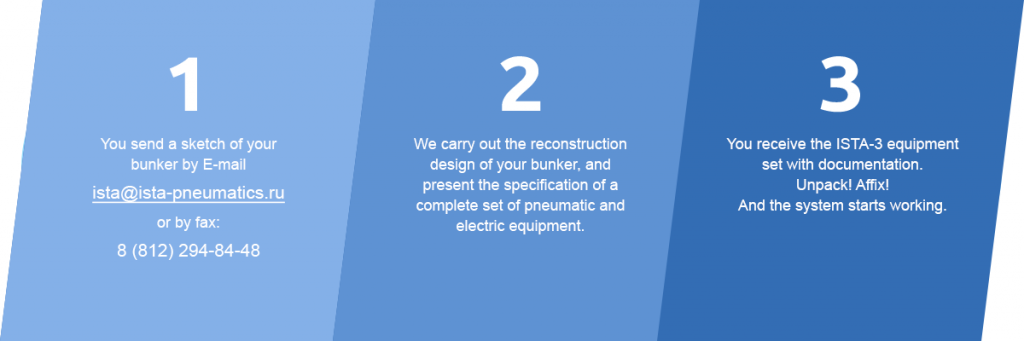

TAILORED DESIGN

We implement the design within a short time based on our experience. In this case, a reference list of previously completed similar projects with contact data of operating specialists is sent to a client. We are ready to supply both the simplest solutions and the air caving systems, integrated into the Process Control System. Full set of certificates and permits will ensure the possibility of operating devices in any production.

SERVICE SUPPORT

Due to the fact that the ISTA company is the Manufacturer and developer of this equipment, you can always get a qualified consultation on the operation, order a set of spare parts or an additional air cannons in the catalogue. A number of our clients have being used the ISTA-3 air cannons for 20 years or more.

TYPES OF FACILITIES, EQUIPPED WITH THE ISTA-3 tm AND ISTA-4 tm SYSTEMS

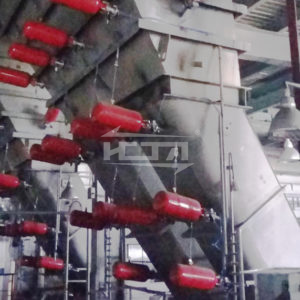

The pneumatic collapse systems based on the ISTA-3 tm and ISTA-4 tm air cannons are applicable not only for different types of bunkers and silos, but as well as for a number of other industrial facilities: boilers, gas flues of heat exchangers, hose and other filters, dustlines and air transport systems, etc.

Besides, our experience has confirmed the effectiveness of the joint use of air guns and other systems, for example vibrating bottoms or industrial vibrators. These already existing systems can be supplemented with the ISTA-3 tm air guns for achieving the necessary effect.

BUNKERS AND SILOS

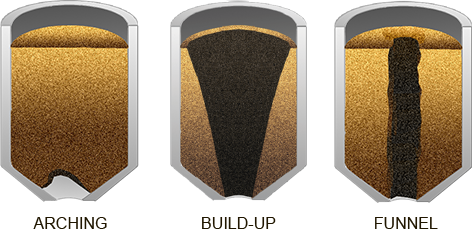

Often during transportation and storage of various bulk materials in the bunkers (silos), it occurs the hanging of the material.

Bulk material hanging in bunkers makes it difficult to unload, may cause a decrease of productivity of the whole line (or even its stopping), product degeneration, which causes serious material consequences.

HEAT EXCHANGE SURFACES OF BOILER UNITS

During the combusting the various types of fuel in boilers, combustion products contain ash small parts, which settle down on the radiation and convective surfaces of the boiler units heating and heat exchangers. These deposits significantly reduce the heat transfer, and accordingly the efficiency of the installation.

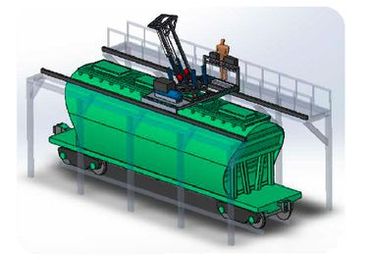

WAGONS CLEANING

In the summer period, the unloading the bulk material from wagons is often not a problem, however, in the winter period, the materials are frozen. During the unloading by means of rotary wagon dumper, some of the frozen material remains. For the final cleaning of wagons the manual labor is used, which essentially slows down the process (from several minutes to several hours).

COMBINING THE SYSTEM

If at the facility, equipped with an industrial vibrator, vibrating bottom or polymer spraying, the problem of bulk material hanging is not solved completely, we recommend to do without its dismantling, and to supplement the existing system with the ISTA-3 tm aircannons. Such a combined systems produced good results on a number of facilities.

CYCLONES, FLUES, BAG FILTERS

The exhaust gas, contained various small particles, passes through the mechanical cleaning stages, for example in the units such as cyclones. Gas passes through the cyclone, with deposits accumulating in the various internal parts of the housing (in the recirculation zones), which subsequently reduce the speed of the gas flow and, consequently, the cleaning.

GALLERY OF OUR WORKS

WE WILL BE GLAD TO COOPERATE WITH YOU!

OUR CLIENTS

- All

- Chemical industry

- Construction industry

- Metallurgy industry

- Power industry

- Food industry

- Pulp & Paper industry

- Mining industry