Research and Modeling

Our company was formed by laboratory staff, who have remained committed to a scientific approach in designing and creating new product samples. New young employees have added modern approaches to experiment and modeling.

The company conducts systematic experimental and numerical studies, the result of which are algorithms and numerical models of processes that determine the operation of specific devices.

On the basis of computer modeling, the initial design variant of the basic parameters of the product is chosen. This approach ensures the development of competitive products in the shortest possible time.

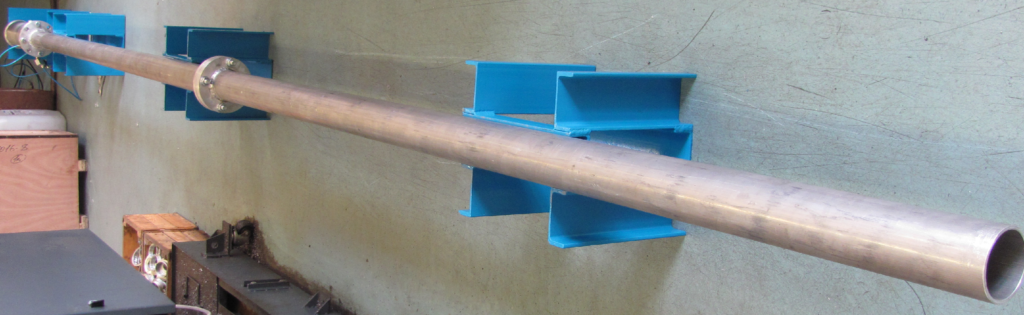

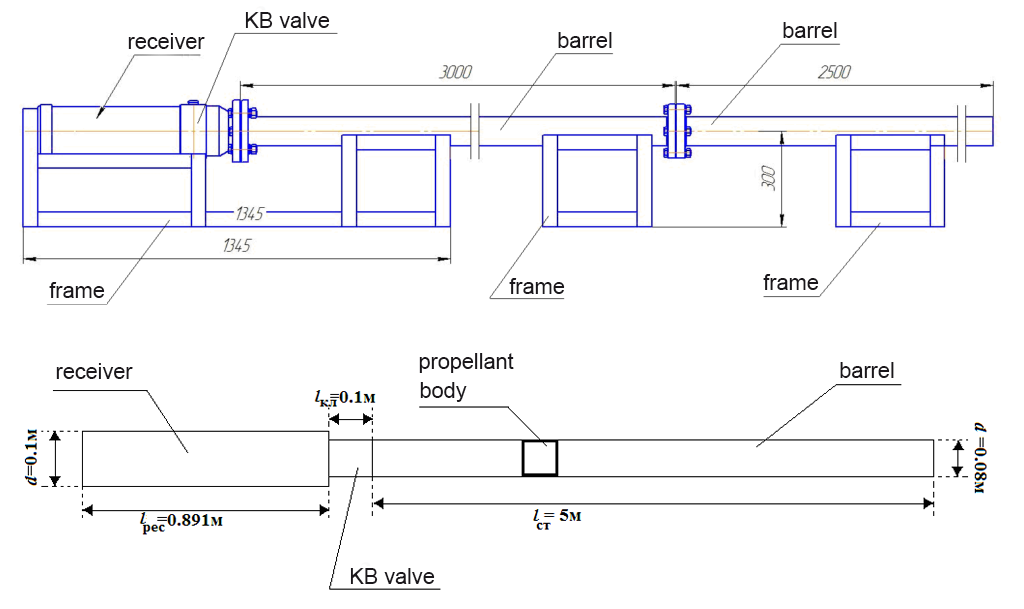

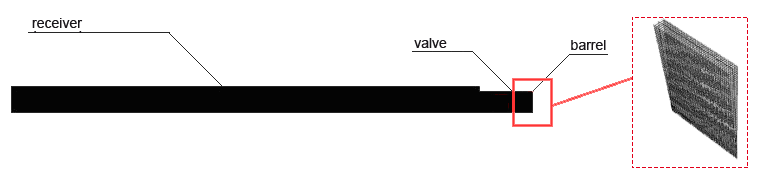

The view of the device, as well as the dimensional drawing and the calculation scheme of the mathematical model is presented below.

Numerical simulation is performed on the basis of the solution of the three-dimensional Navier-Stokes equations. The Figure below shows the calculated spatial grid with a movable boundary at the end of the projectile. At each time step, a pusher force is calculated that determines the Propellant Body (PB) acceleration and the grid shift.

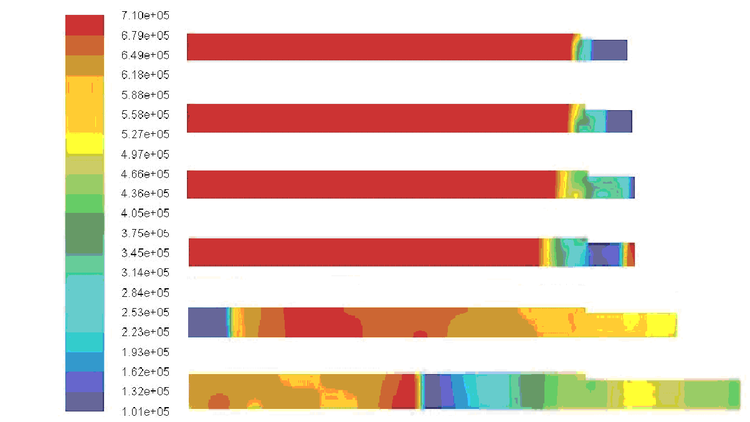

The results of the calculation of the pressure shown in the pictures on the left, show the nonstationary nature of the gas flow, in particular, the inhomogeneity of the pressure in time and in space. Accurate coincidence of the most important characteristics, calculated and measured by the time-of-flight method, for example PB velocities on the trunk section, allow using a numerical procedure for pre-project optimization of the device parameters. At present, we are implementing computational models that take into account the complex geometry and the finite time of the valve opening.

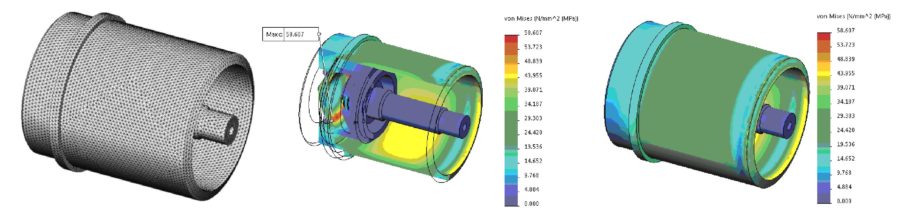

As an example, the calculation of the strength characteristics of the valve of the linethrower: the mesh of the finite elements of the assembly of the high-speed valve, as well as the field of equivalent valve stresses using the Mises criterion are shown. Based on these and many other calculations, the ISTA-240 linethrower was upgraded.