MAIN ELEMENT OF THE ISTA AIR CANNON IS A HIGH-SPEED VALVE, MADE ACCORDING TO THE SPEED VALVE TECHNOLOGY

High speed of valve opening allows to use for caving the hangings of loose materials not only impulse of compressed air jet, but also formed in barrel a shock wave.

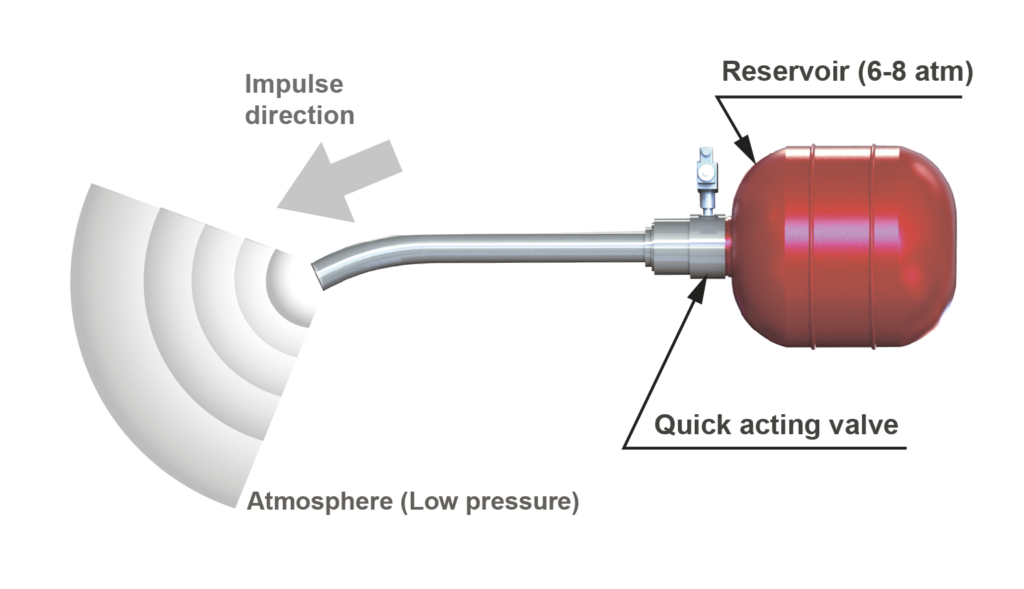

The air cannon consists of three main parts: receiver with pressurized under 6-8 atm air, high-speed valve (controlled with an air electric valve), as well as the barrel in diameter 40 or 80 mm. In case of operating the air electric valve, the high-speed valve is opened. Compressed air from the receiver flows out into the barrel with a supersonic speed, generating the shock wave. This combination of supersonic jet and shock wave provides the effective fluidization of the material.

Unique advantages of the ISTA air cannons

RELIABILITY

The air cannon operating term is composed at least 10 years in the standard mode, which provides multiple paybacks. Warranty period on unloading system of bulk materials is composed 12 months

SAFETY

The air cannon is recognized as a specimen of safety equipment – information is given detailed in the magazine – Workplace safety in the industry. The electric power supply with a voltage in 24V is used to control the cleaning system of bunker.

VERSATILITY, EFFECTIVENESS

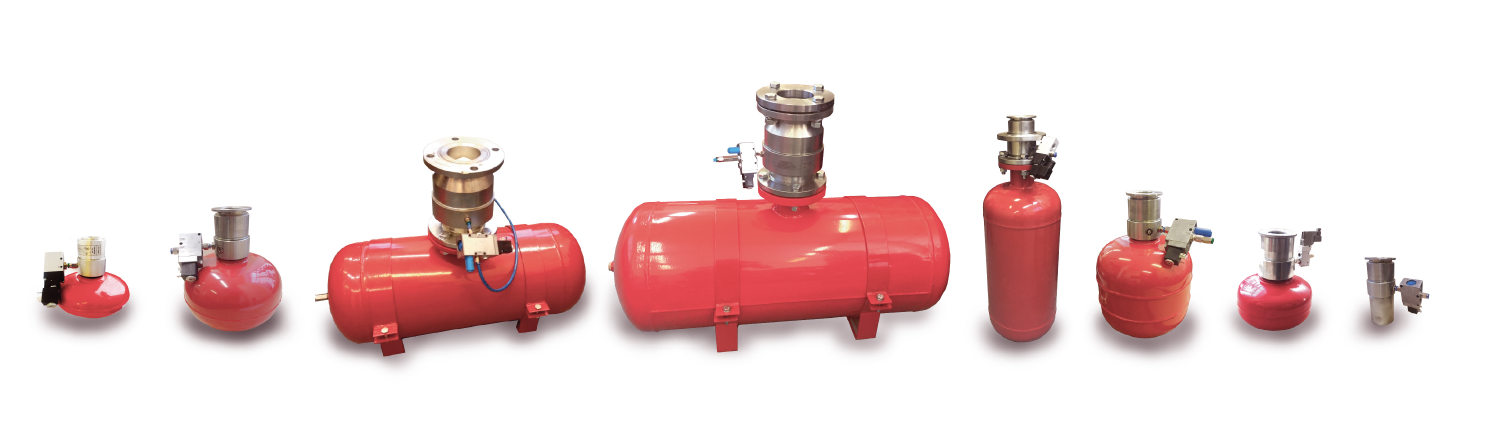

The air cannons are applicable both to eliminate hangings in the bunkers, to removal “plugs” in the air transport channels, and to clean heat exchange surfaces. The problem of cleaning bunkers, both small (with a capacity of less than 1 m3) and large (10 000 m3 and more) is being solved.

MANUFACTURABILITY

Reconstruction of the bunker during the installation of the air cannon systems reduces to the insertion in its walls of the 1.5 “gas and water pipes according to our design; the air cannons are easily installed (weight from 4 kg). In case of operating aircannon, the sound does not exceed the noise level in the workshop.

EASE OF ASSEMBLY AND CONTROL

Delivery set allows the Customer to assemble the entire system on the basis of the aircannons for several hours independently; as well as the set may include a portable compressor. Control of the bunker cleaning system is possible in automatic and / or in manual mode. The system is easily built into the Process Control System.

ECOLOGICAL AND SMALL CONSUMPTION

Lubrication absence of moving elements in the aircannons allows direct contact of compressed air with food products. Minimum consumption of the compressed air. One aircannon consumes from 1 liter to 150 liters of the compressed air per one start.